Inerting to make petroleum tanks safe for removal

No matter how old or empty an underground or aboveground storage tank (UST/AST) may be, it’s imperative that those removing them take extreme caution. If the tank held fuel (as they often do), flammable vapors fill the void in the tank long after the liquid has dissipated. If ignited, the explosion can turn a tank basin into something much more sinister.

That is why those who pull tanks must first carefully remove two elements of the fire triangle – oxygen and the fuel source (the third is an ignition source) – to reduce the probability of a fire or explosion. Typically, this is accomplished by extracting volatile vapors through a vent in a process called inerting.

How it works

One tried-and-true method CGRS technicians use to inert a tank is to line the bottom of it with dry ice (carbon dioxide frozen to a solid). The industry standard requires a minimum quantity of 15 to 20 pounds of dry ice per every 1,000 gallons of the tank’s capacity. For example, inerting a 10,000-gallon tank requires at least 150 to 200 pounds of dry ice.

The melting of dry ice from a solid to a gas is a process called sublimation. Using dry ice is an effective method because, as a gas, carbon dioxide is a denser molecule than oxygen. Thus, as the dry ice melts inside of the tank, it forces the oxygen out of the tank.

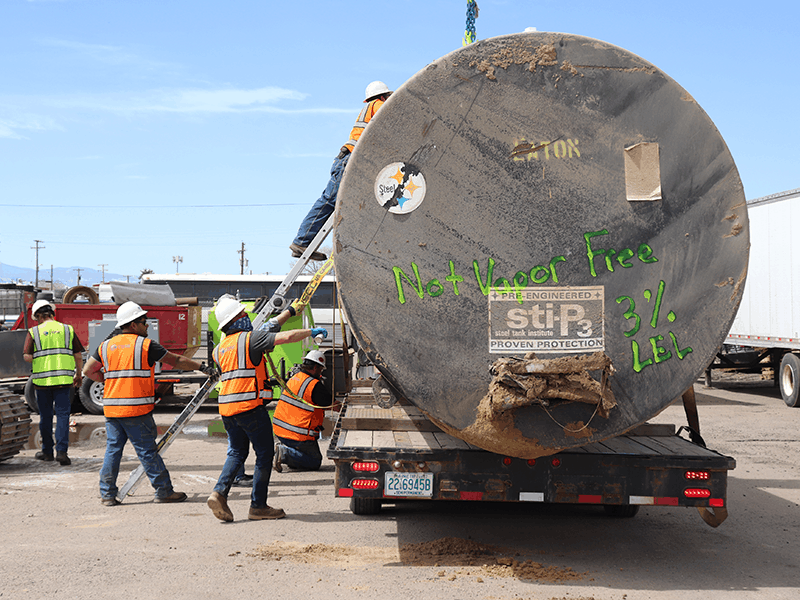

After inserting the dry ice, a calibrated air quality meter helps monitor the oxygen and lower explosive limit (LEL) in the tank’s atmosphere. Per Colorado Division of Oil & Public Safety (OPS) regulations, a tank is only considered safe for removal once the oxygen levels are less than 5% OR the LEL is 10% or less. When these criteria are met and all other safety precautions are accounted for, a tank is ready for removal and transported off site.

Call a CGRS Expert:

800.288.2657

Matt Newcomb

Environmental Services Project Manager/Staff Geologist

Challenges

Because of the harsh atmospheres – such as high LELs, or low oxygen and high carbon dioxide – in empty USTs, failure of tank atmosphere monitoring equipment is always a possibility. But with the right equipment, problem solving and precautions, challenges are avoidable.

However, more extreme hot or cold weather conditions present some obstacles that can’t be avoided. For example, vapors become denser in hotter temperatures, tend to accumulate in low places and don’t flow out of vents as quickly. To combat this, CGRS technicians may add a greater quantity of dry ice or, in some cases, small amounts of warm water or an environmentally friendly, non-toxic cleaning product. This technique, called encapsulation, “suppresses hydrocarbon molecules and renders flammable liquids and vapors nonflammable,” according to Recommended Practices for the Closure of Underground Storage Tank (PEI, 2020, p. 12). Other methods may include simply shading the UST from direct sunlight, when possible.

Similarly, during the winter, temperatures may be too cold for dry ice to go through the process of sublimation and it may remain a solid, making it near impossible to inert a tank. The best way to avoid this issue is to schedule tank removals when temperatures are well above freezing.

To ensure your petroleum tanks are removed safely and correctly, contact the tank experts at CGRS: 800.288.2657.

Source: Petroleum Equipment Institute (2020). Recommended Practices for the Closure of Underground Storage Tank and Shop-Fabricated Aboveground Storage Tank Systems.