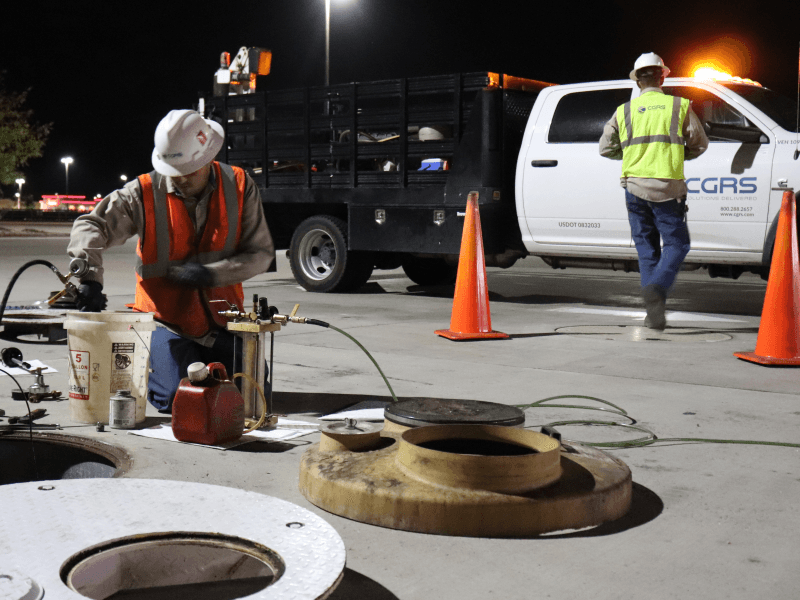

FUEL SYSTEM COMPLIANCE SERVICES

CGRS qualified technicians offer a wide variety of reliable UST and AST compliance testing methods and inspection services. We understand which regulations can affect our customers’ bottom line, so we take a holistic view of every site’s needs, address upcoming regulations that may have a financial impact, and help develop a plan to sustain profits.

Testing Services

AST and UST Tank Inspection Services: Our American Petroleum Institute-certified inspectors provide ultrasonic testing and an internal/external tank inspection.

Equipment Survey and Facility Inspections: The purpose of this service is to document the current facility conditions, equipment and compliance status. It is useful in property transactions or as a facility-management tool.

Secondary Containment Testing: EPA regulations updated in 2015 now require secondary-containment testing. This includes testing spill buckets, submersible turbine pump (STP) containment and under-dispenser containment. In some instances secondary-containment testing on piping and tanks may be required. Your state regulations will provide details on dates, deadlines and testing requirements.

Tank Tightness Testing: CGRS uses a variety of tank-tightness methods that comply with EPA and state requirements including volumetric and non-volumetric testing of USTs and ASTs. CGRS is a licensed Tracer Tight® affiliate.

Dri-sump® Containment Tightness Testing: An EPA-approved containment-tightness testing technology that delivers digitally recorded pinpoint testing accuracy to 0.05 gph in just 60 seconds.

Line Tightness Testing: Our certified testers employ a variety of methods to ensure your fuel system’s compliance with applicable regulations.

Electronic/Mechanical Leak Detector Testing: In order to ensure that equipment is functioning properly and to meet testing requirements for automatic line leak detectors, CGRS performs calibrated leak simulations to verify positive shutdown or flow restrictions.

Cathodic Protection (CP) System Testing: Our NACE-certified Corrosion Testers inspect both impressed current and galvanic systems. They ensure that these systems provide adequate corrosion protection to all metal portions of the fueling system which come in contact with the ground and that routinely contain product.

Air Quality Testing: We provide air quality testing services to comply with federal, state and local regulations including NESHAP (National Emission Standards for Hazardous Air Pollutants), Regulation 7 in Colorado, CARB (California Air Resources Board) or other applicable regulations in your area. NESHAP (subpart CCCCC) establishes national emission limitations and management practices for hazardous air pollutants (HAP) emitted from the loading of gasoline storage tanks at gasoline dispensing facilities.

Fuel Maintenance Program: This is effective on fuel stored for long periods of time as with backup generator systems. This service includes fuel sampling, analysis and possible implementation of an additive program to prevent repolymerization.

Records Management

We can file all your paperwork with government agencies and remind you about required annual tests. We electronically store and track all of your compliance reports over the years so we can provide them at a moment’s notice.

Remote Tank Monitoring

We offer remote ATG monitoring, monthly reports, alarm systems, hosting and much more.

Fuel Quality Services

Problems with water and degraded fuel in underground tanks can be a costly nightmare for fuel retailers and commercial fuel users.

CGRS and our partners provide a comprehensive solution for removing water from fuel reserves as well as a complete tank-cleaning and fuel-restoration service to ensure premium quality for all fuel types – including gasoline products and diesel – at all times.

Our comprehensive solution includes removing water, particulate and biological contamination from fuel reserves, as well as a complete tank cleaning and fuel restoration service; biocide and fuel conditioners are added as necessary.

Operator Training

CGRS offers small classroom settings as well as online courses for owner/operators to earn their Class A/B Operator Certification.

Frequently Asked Questions

Are compliance reports and testing required annually? Yes.

How much is this going to cost me? There are no hard and fast rules here. It depends on what you need.

How soon can you be here? We typically schedule two or three weeks out; however, we can accommodate more urgent appointments.

Can you help me with a request for records from a state inspector? If you are our customer, we can submit that information for you at no charge.

I’m confused by all the local, state and federal requirements. We are experts in the regulations; we can explain them and provide you with the most cost-effective solution.

Does my tank need testing? Tank tests are relatively expensive. If we can help you avoid that scenario, we will.