Project Profile: W. Colfax Remediation System Installation

Denver, Colorado

We often joke at CGRS that it is impossible to give an elevator speech about what we do because of how diverse our service offerings are. But the reality is, more often than not, that diversity really comes in handy. Projects sometimes evolve significantly from their initial scope of work, and when that happens, we have the expertise and coordination to safely and confidently turn the reins over to the other experts on our team.

This example dates back to 1991 when evidence of a fuel release was discovered at the West Colfax U-Pump-It site. At the time, geotechnical soil borings were being drilled on adjacent properties that were under development. Between 1992 and 2006, investigations and injection remediation activities were performed (by consultants other than CGRS). To complicate matters, groundwater contamination from a chemical release at a nearby dry-cleaning facility was discovered below the U-Pump-It site. This forced a halt to the work on site while the initial chemical release was investigated and remediated.

It wasn’t until 2014 that work on the U-Pump-It site resumed. This time with CGRS as the environmental contractors. We began by investigating the extent of the petroleum hydrocarbon contaminants in the groundwater as well as performing remediation pilot testing. In 2019 the Division of Oil and Public Safety (OPS) approved a corrective action plan (CAP) prepared by CGRS. This plan included hydraulic fracturing to create permeable zones in the fine grain soils of the shallow perched aquifer, installing air sparge and soil vapor extraction wells, and piping to remediation system equipment.

Stage I of the remediation plan was to install air sparge and soil vapor extraction remediation system wells where groundwater contaminant concentrations were most elevated. This was in the contaminant source area around the underground tank (UST) system where the fuel release occurred. This is the point at which our environmental remediation team got our environmental construction team involved in the project.

Call a CGRS Expert:

800.288.2657

Gregg Neurohr, PG

PM/Geologist

gneurohr@cgrs.com

Call a CGRS Expert:

800.288.2657

Mike Helburg

PM/Superintendent

Environmental Construction

mhelburg@cgrs.com

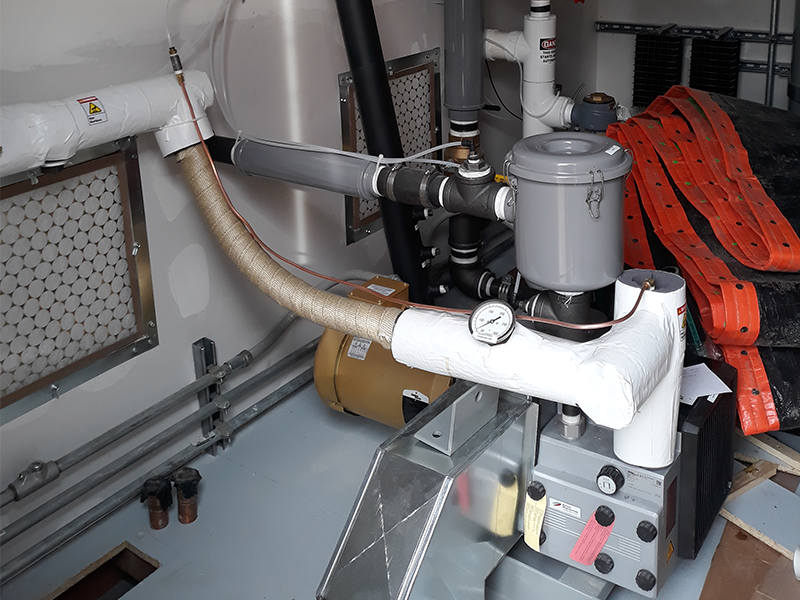

In October of 2019 the CGRS environmental construction team got to work performing system expansion installation work. Prior to beginning construction work, seven soil vapor extraction wells and four air sparge wells were installed. The construction crew added two horizontal soil vapor extraction wells in addition to the 11 wells already on site. Remediation system construction work included cutting and removing concrete, excavating trenches and installing piping from the remediation wells to the remediation system equipment shed, per plan specifications. Piping was then connected to the remediation system equipment inside the shed and the work area was repaved with concrete. This leg of the project took about two months to complete due to weather restrictions and shed settings.

Stage II of the remediation system proved to be very effective in cleaning up the groundwater contaminants affecting the source area. In 2022, OPS approved CGRS’s proposed CAP modification to expand the remediation system to address groundwater contaminants in outlying areas of the site. Reports from the 1990’s documented the presence of hydraulic fracturing activities located in the areas planned for system expansion, like those completed during the first phase of the remediation project. The CAP modification includes installing seven additional air sparge and nine additional soil vapor extraction wells in those areas.

To date the new remediation wells have been installed. As in Stage I, CGRS’s remediation construction team has initiated work including concrete removal and replacement, trenching and piping installation to connect the new remediation wells to the previously installed remediation system equipment. Activation of the expanded remediation system is planned for late October 2022.