Project Profile: Vandenberg Space Force Base Fuel System Repair

The Vandenberg Space Force Base Fuel System Repair project is a great opportunity to illustrate the ins-and-outs of taking a project like this from proposal to completion. The scope of work for this fuel system repair project was significant, requiring the installation of 12 double-wall under dispenser containments (UDCs) 4 double-wall fiberglass piping sumps, and 3 double-wall fill sumps to attach to the existing double-wall fiberglass tanks on site. The project also required the installation of a new Bravo double-wall vent box. From pre-installation construction to final testing, a project like this will take about 3 months.

Start to Finish

The most important step in every project we perform is addressing all safety considerations. For this project that included creating a site safety plan (HASP), marking the locations of utilities, notification of dig alert prior to excavation, site preparation for construction, lock-out tag-out of all electrical to dispenser islands and tanks, and pre ELD leak locate testing.

Next was the demolition phase during which all product lines were flushed using nitrogen. Dispensers were decommissioned and put into maintenance mode prior to removal.

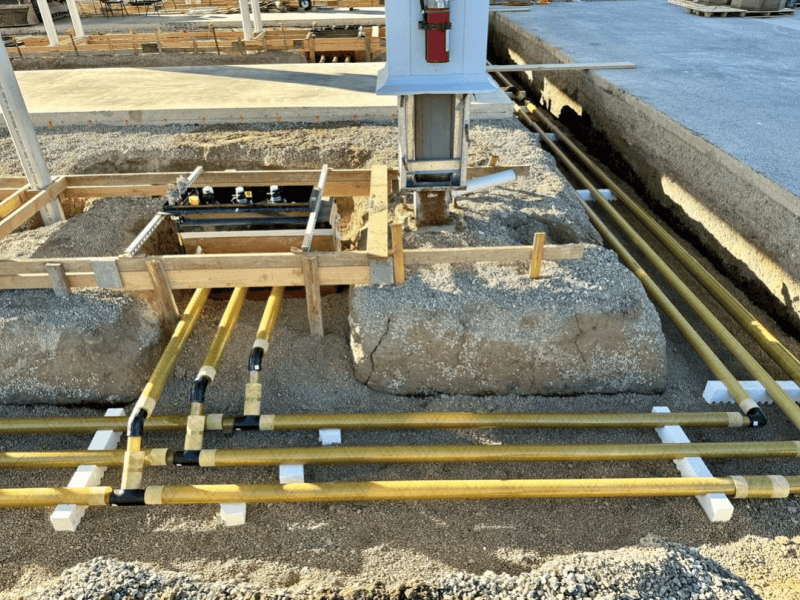

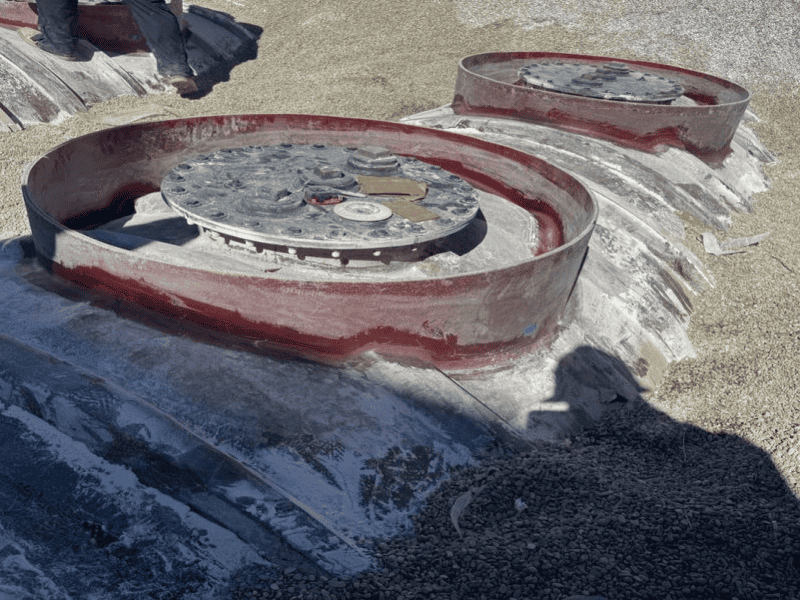

Once on site the team proceeded with UDC staging and construction along with gravel removal and the installation of seven new 48” Xerxes Double Wall Tank Collars and seven new Bravo Double Wall Tank Sumps. Next we plumbed the STPs/turbines, fills, piping/electrical penetrations. The Tank Sumps were coated with four extra layers of fiberglass lamination around all the seams and penetration fittings.

Call a CGRS Expert:

800.288.2657

Matt Thomas

California Construction/

Compliance Manager

Mobile: 626.627.8316

The last step of the UDC penetrations was completed by encapsulating each one with 4 layers of fiberglass lamination, this provides an added layer of insulation for a worry free VPH system. Once completed we moved on to setting the UDCs and fiberglass piping installation.

One unique aspect of this project is that these are some of the very first Bravo Double Wall Tank Sumps ever installed on Xerxes tanks. It is typically mandatory to install and use Xerxes sumps with their tanks, but we received special approval to proceed with the Bravo brand equipment.

Final Touches

The final phase of work will include the installation of the tank top equipment, new product, vapor recovery and vent piping. Then on to inspections of all new piping, sumps, UDCs and vent box before back filling. This final phase is always a satisfying one, getting all that hard work tucked safely under fresh concrete. The goal is to get the project done safely, on time, and on budget. This project is one we are proud of! It is a privilege to be a trusted contractor for the Vandenberg Space Force Base.

If you are looking for a fuel system design, repair, or upgrade, don’t hesitate to contact CGRS. Let us do the heavy lifting to get your system functioning safely, efficiently, and profitably.