Don’t water down the importance of detecting H2O in fuel

Detecting water in fuel tanks is critical to preventing phase separation and astronomical costs associated with disposing of and replacing wasted gas.

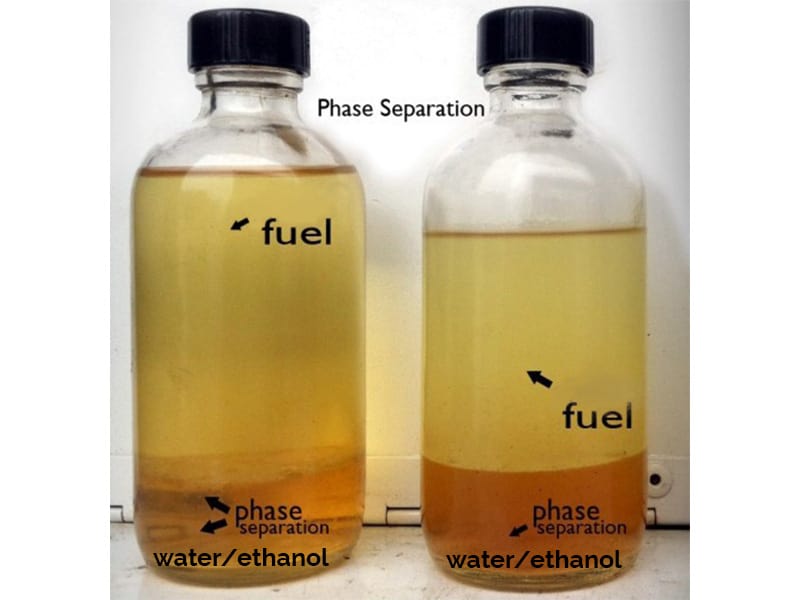

Since the introduction of gasoline-ethanol blends, detecting water in a petroleum UST has become trickier as water in the tank will pull the ethanol out of the gasoline solution, a process known as phase separation. This water/ethanol mix will then sink to the bottom of the tank and has a different specific gravity than water. And that is what can cause trouble.

Because the water/ethanol mixture is lighter than water alone, traditional automatic tank gauge (ATG) water floats won’t detect it and it could end up in customers’ vehicles. Without the ethanol, the fuel will no longer meet the octane rating, often causing engine problems that require attention. However, if customers pump the ethanol/water mixture into their vehicles, it will wreak havoc with their engines and result in expensive repairs for which the gas station’s owner/operator could be held responsible.

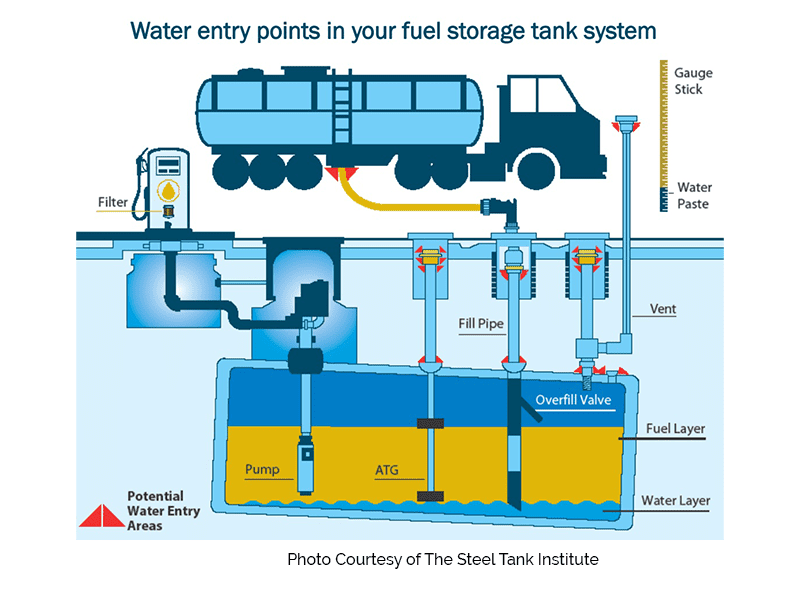

Water in a petroleum UST can also affect the integrity of the fuel system, damaging components such as leak detectors, pumps and dispensers. It can also cause microbial contamination and irreversible tank pitting if left unchecked for too long, potentially leading to costly repairs.

“You have to know at all times how much water is in your tank,” said Mark Shaw, CGRS Compliance Services Operations Supervisor.

You can check for water manually or use an automatic tank gauge (ATG).

Call a CGRS Expert:

800.288.2657

Kylene Baker

Compliance Administrative Manager

Call a CGRS Expert:

800.288.2657

Mark Shaw

Compliance Services

Operations Supervisor

Mobile: 916.997.8921

Manual water detection

Owners/operators and fuel delivery drivers can check the water level in tanks manually by applying a water-detecting paste to a gauge stick and inserting it into the tank through the manway. For accurate results, this should be done daily – at a minimum – as well as before new fuel is added to a tank and after heavy precipitation or flooding of the site.

If you use the appropriate water-finding paste, this process will detect water even if it’s mixed with ethanol. The obvious downside is this method relies on a person to go out and “stick” the tanks. The more tanks involved or the less attentive the person is, the more likely they will miss the presence of water in a tank – a mistake that could be costly, depending on factors such as how much water was in the tank and how many customers filled their vehicles with fuel from that tank.

It doesn’t take much water in the tank to cause phase separation: the smaller the tank or the less fuel in the tank, the less water it will take to cause a problem.

Water floats versus Phase 2 floats

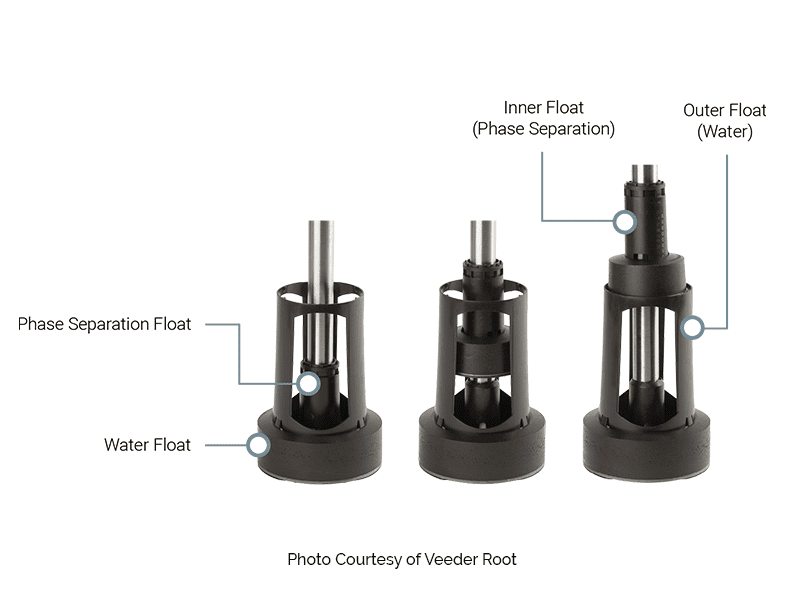

Most USTs have ATGs that alert the owner/operator when it detects water once it reaches a predetermined programmed level, such as a half inch or an inch. However, traditional ATG floats only detect water – not water mixed with ethanol.

“That water float will never tell you if you have phase separation,” Shaw said.

ATG Phase Separation floats can detect when water or the ethanol-water mixture has reached a pre-set depth, triggering an alarm so that the owner/operator can take action to prevent customers from accessing the fuel in the affected tank.

With the cost of fuel rising daily – or faster – the price of not detecting water or phase separation in a fuel tank gets heavier by the minute. Contact CGRS Compliance Services at 800.288.2657 to discuss the best detection option for your fuel system.