CGRS sump testing goes waterless, faster with Dri-sump® method

CGRS’s Compliance Services division is now able to perform underground storage tank (UST) containment testing using the company’s waterless Dri-sump® system.

The Dri-sump® testing method will reduce the amount of time to test each containment and minimize disruptions to fueling operations. It also means compliance technicians don’t have to bring hundreds of gallons of water to sites to perform hydrostatic testing and dispose of the hazardous waste afterward.

The U.S. Environmental Protection Agency (EPA) requires UST owners/operators nationwide to test their systems’ containments every three years unless they are double-walled and checked every 30 days for liquid in their interstice. Some states may require containment testing more frequently. The Dri-sump® testing method is EPA approved.

The hydrostatic method requires technicians to pour water to a level 4 inches above the highest penetration or joint in the sump sidewall, which can require 150 to 200 gallons of water for one sump. Technicians then compare the water’s beginning depth to its depth after an hour to see if it has changed by one-eighth of an inch or more. If it has changed, a leak is present and the technicians must engage other methods to pinpoint the leak’s location.

Photos courtesy of Leighton O’Brien

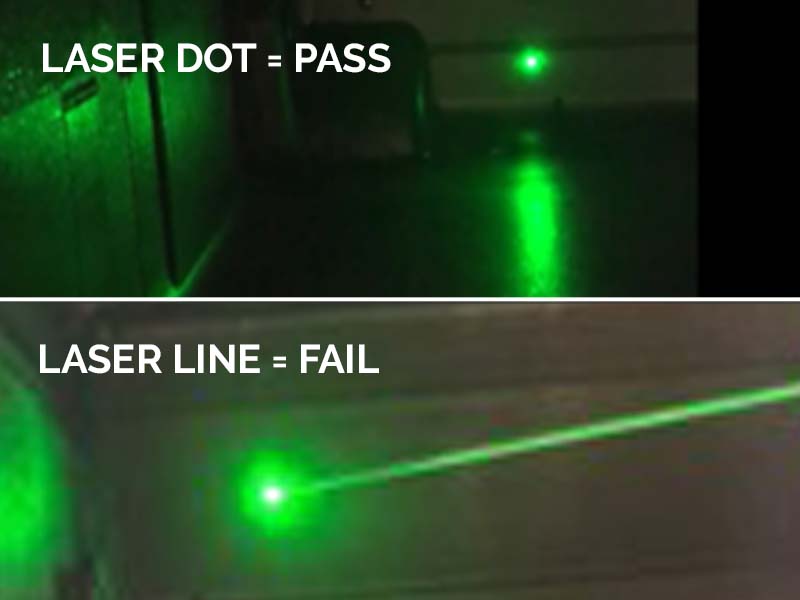

Instead of water, the Dri-sump® system uses a food-grade, pH-neutral, nonpetroleum vapor aerosol injected into the sump, filling a 300-gallon sump in 10-15 seconds. An air generator pulls the gases from the sump into a viewing chamber connected to a Vapor Stimulator Tube (VST), where a laser delivers the verdict: a “dot” means no leak is present and the sump passes the test; a green “line” means the sump is leaking.

A mobile app captures the laser result, time stamps it with the GPS location and uploads it into data capture software for analysis and reporting. The laser line pinpoints where the leak is, so no additional testing method – only repairs to the containment system – is necessary.

Other benefits of Dri-sump® testing include:

- Less dispenser downtime

- Increase number of containment tests per day

- The vapor dissipates within 10 minutes after the test is completed

- It is the only test that can be conducted in frozen soils, high water table conditions and any backfill soil type

- Regulatory acceptance as an alternative to costly hydrostatic testing

“Dri-sump is an innovative technology that allows CGRS to deliver a better solution to our compliance customers,” said Mark Shaw, CGRS Compliance Services Operations Supervisor. “It speeds up containment testing exponentially, saving customers time and money while they’re still adhering to compliance regulations.”

CGRS can perform Dri-sump® containment testing nationwide. To schedule your UST-containment testing with this new technology, call a CGRS Compliance Services expert at 800.288.2657.