COMPRESSED NATURAL GAS (CNG) SERVICES

CGRS designs and builds as well as provides service/maintenance to compressed natural gas (CNG) facilities and stations for the private and public sectors throughout the Rocky Mountain region and beyond. We are also a respected CNG leader and a Registered Service Agent for certifying CNG dispensers under the Colorado Division of Oil and Public Safety (OPS) Weights and Measures Office.

Building CNG fuel facilities is a specialized and increasingly regulated process. Not only does CGRS have the experience and capability to expertly deliver a successful CNG project, but we offer value engineering, working with customers to accommodate their budget and allowing for expansion of their facilities in the future.

CGRS’s CNG capabilities include:

- Government fueling-facility conversion & maintenance

- Truck stop CNG fueling systems

- Wastewater biogas conversion to CNG

- Dairy biogas conversion

OPS Registered Service Agent

As an OPS Registered Service Agent, a qualified CNG Construction Services team member for CGRS can calibrate and certify that CNG dispensers are providing the amount of fuel – within 2 percent – that they say they are. It also means CGRS can make adjustments on meters and seal all components of CNG dispensers per National Type Evaluation Program, a nonprofit organization that evaluates scales and other weighing equipment to ensure it meets all government standards and requirements.

CGRS is one of only a handful of companies in Colorado with the experience to inspect and evaluate CNG facilities as well as make repairs to bring sites up to code. OPS, in accordance with the National Fire Protection Association (NFPA) 52 Vehicular Natural Gas Fuel Systems Code, requires CNG pressure relief valve re-certification every three years.

Call us for a free consultation about your CNG-delivery needs!

Compressed Natural Gas (CNG) Project Spotlights

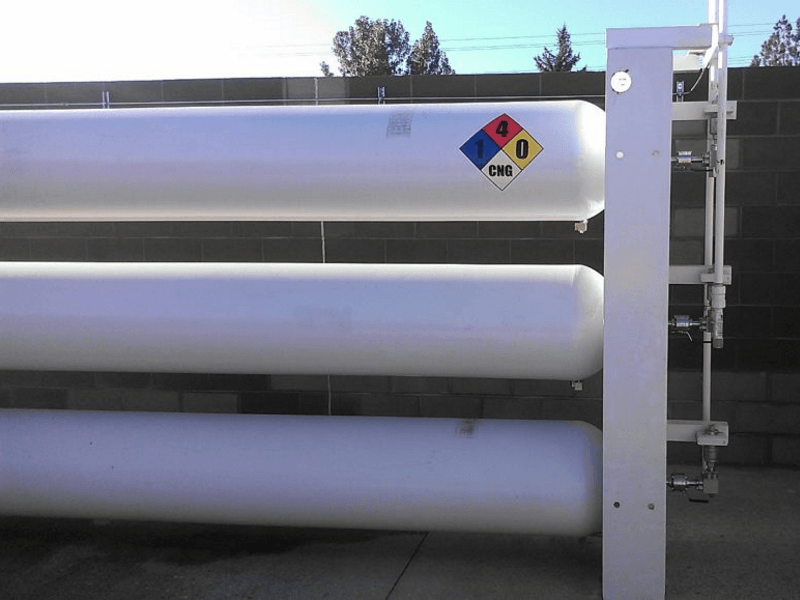

Public Works Facility – Cheyenne, WY

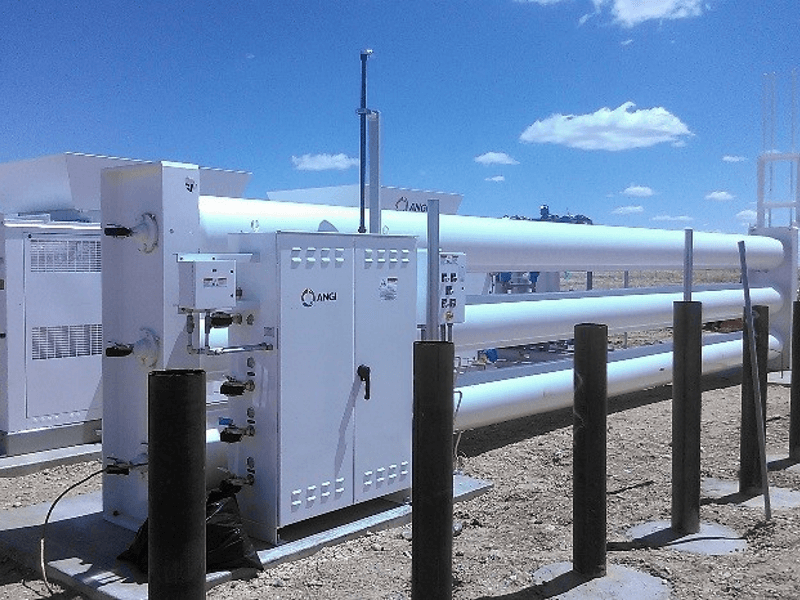

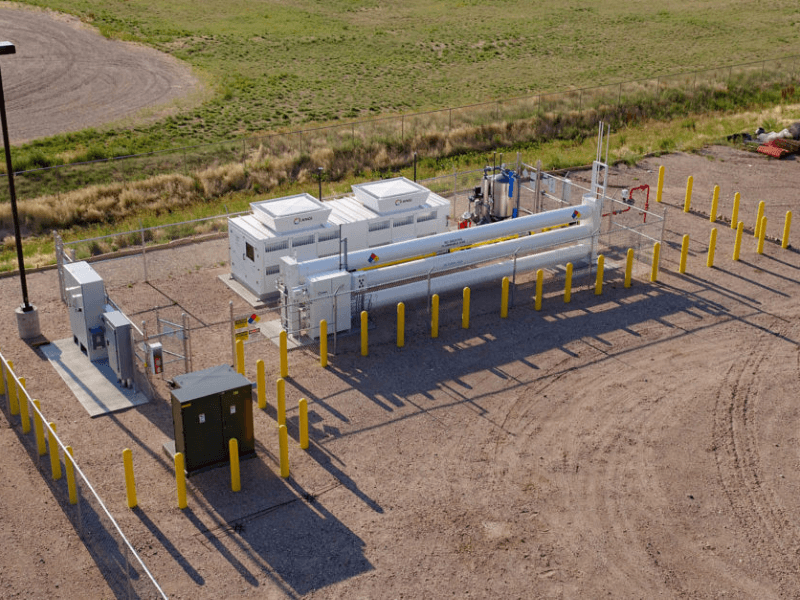

CGRS constructed an 800 scfm compressor station, including 10 time-fill stations and a fast-fill dispenser with heavy-duty fueling using ANGI equipment, from the ground up. The project entailed installation of all related CNG equipment as well as civil construction for the site. CGRS also holds the current contract for operation and maintenance at this site, which contains a 24/7 emergency-service clause.

Hat Six Travel Center – Evansville, WY

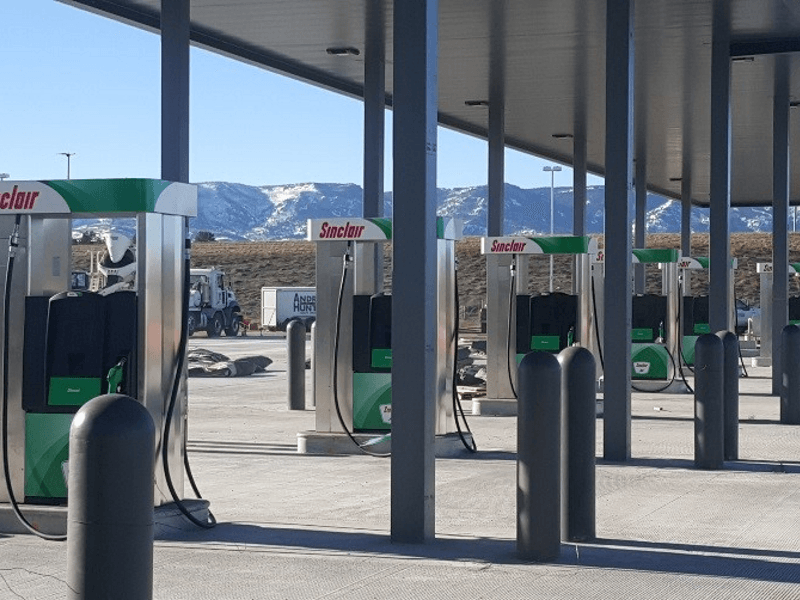

Correcting a mistake is always the right thing to do and is, in fact, part of CGRS policy no matter the cost. Sometimes having that kind of integrity will help not only retain a customer but also earn additional work. That’s exactly what happened in 2014 when CGRS hit a flex line while drilling a monitoring well near the then-Eastgate Travel Plaza, resulting in the loss of half of the travel center’s diesel fuel islands until repairs were made. Per its policy, CGRS not only repaired the line but also reimbursed the center’s owners for loss of business.

The owners were so impressed with CGRS’s integrity and quality of work in doing the repairs, they hired us to design and build the fueling portion of a new travel plaza. The process began in April 2015 and the diesel fueling system was up and running 13 months later. CGRS wrapped up the removal of the old fueling system and tanks that fall. The existing business and fueling system remained open and operational the entire time CGRS and contractor Andreen Hunt Construction, Inc., built the new center, now called Hat Six Travel Plaza, and removed the old fueling facilities.

The nearly $3 million job included installing:

- Two 40,000-gallon, 75-foot-long underground storage tanks (USTs) for diesel fuel

- One 8,000-gallon UST for diesel exhaust fluid

- Two 30,000-gallon, double-wall, fiberglass USTs, one of which holds unleaded and the other is split to hold 12,000 gallons of premium unleaded fuel and 18,000 gallons of diesel

- One 2,000-gallon propane AST and fueling system

- One 15,000-gallon UST for Halliburton’s fueling operations

- Two auto-fueling canopies with seven point-of-sale fueling islands

- CNG infrastructure with masonry equipment enclosure and underground stainless steel piping to future dispensers

- One truck-fueling canopy with eight diesel dispensers including DEF

Once the new center was completed, the owners sold the 13 old fueling dispensers and had CGRS and Andreen Hunt excavate and remove:

- Three 20,000-gallon, two 12,000-gallon and one 5,000-gallon USTs

- The old fueling system for nine truck and four auto dispensers including piping and electrical work

The Hat Six Travel Plaza was the biggest project the CGRS Construction team had taken on at the time.

City of Grand Junction – Grand Junction, CO

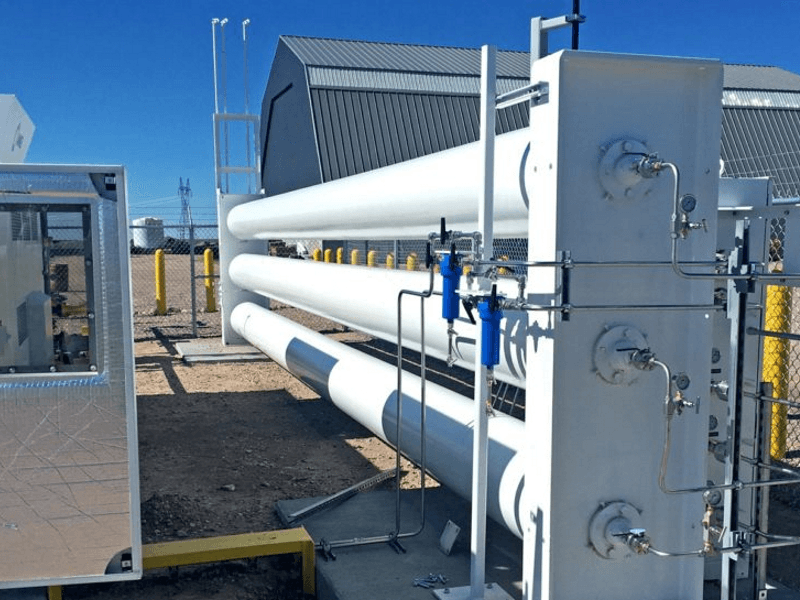

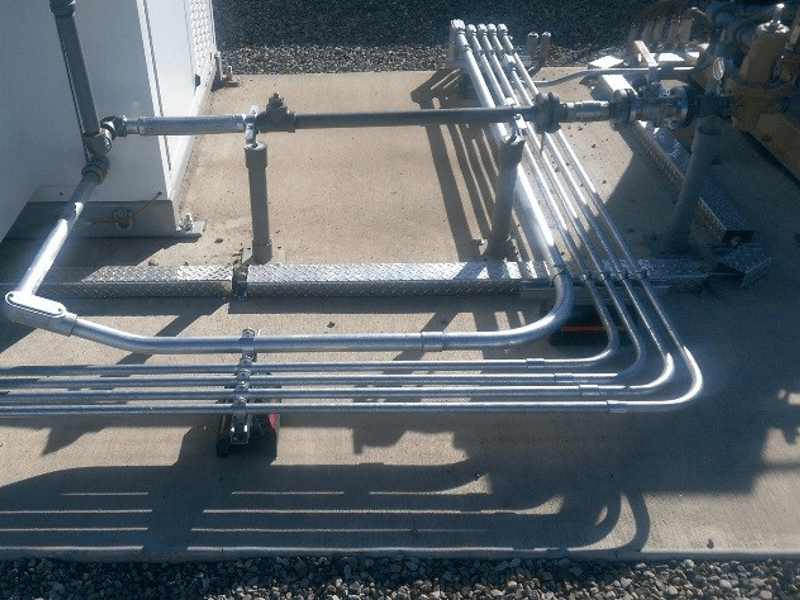

For the City of Grand Junction’s slow-fill/time-fill CNG fueling station expansion, CGRS installed:

- 10 time-fill dispenser hose drops

- Site grading

- Equipment pads

- Fencing/barricades

- Telephone system

- Associated electric and gas

- Plumbing

- Alarm system

- Associated appurtenances

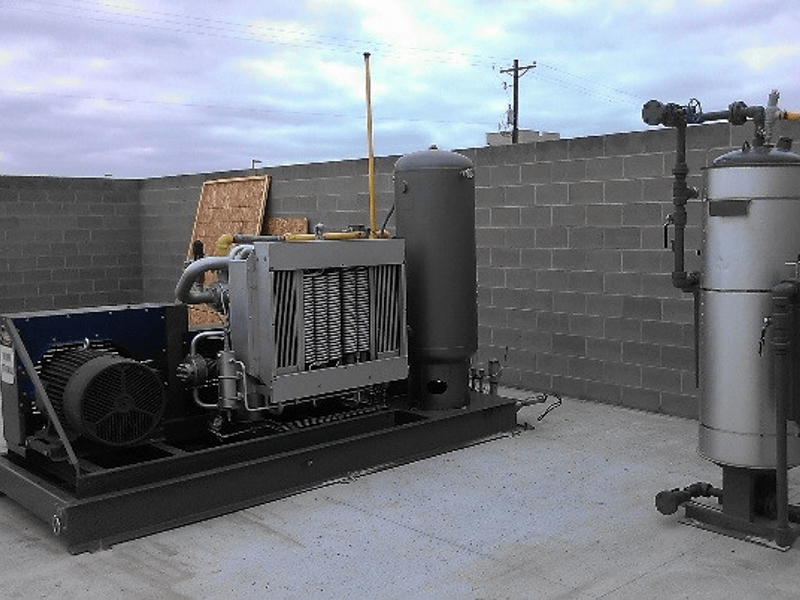

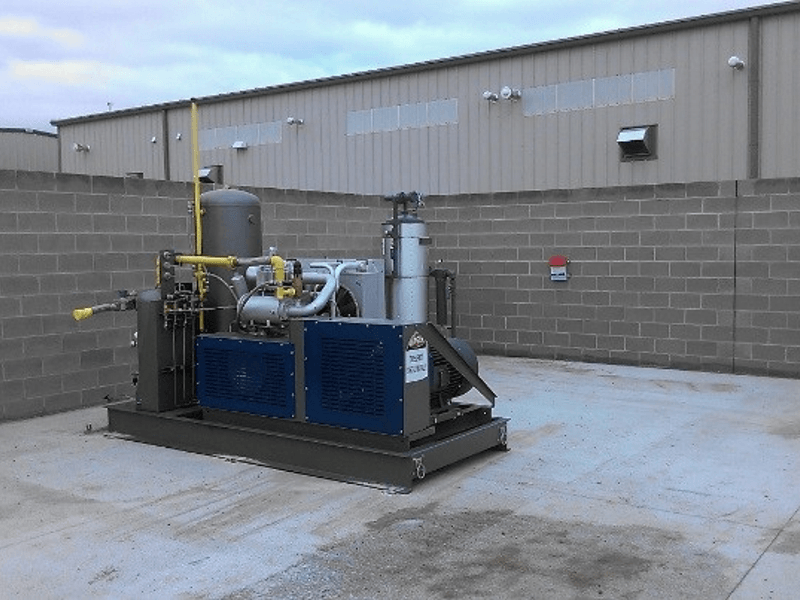

Weld County School District, RE-1 – Gilcrest, CO

The state for Weld County School District RE-1 is designed to handle up to 400 scfm and the equipment enclosure is constructed of split-faced CMU to match the new transportation building, with a capacity for future compressor and storage. CGRS provided design, engineering and construction for a new CNG fast-fill system with a rough-in for future time-fill fueling.